Your digital twin along the supply chain

Success

stories

Logistics is all about moving goods from A to B, isn’t it? Not quite, as the German start-up Packwise GmbH is about to prove. Hidden from consumer view, B2B businesses in various industries rely on standardised packaging systems, such as the Intermediate Bulk Container (IBC) to carry chemicals, groceries, cosmetics, or pharmaceuticals. These containers are reliable, flexible, re-usable or recyclable and circulated all over the world. But they aren’t smart.

Connecting containers

Packwise’s customer base faces an increased need to lower costs along the supply chain. To do so their supply chain can be digitised. As a side effect, their carbon footprint can be reduced. Therefore, industry packaging stock needs to become smart. A digital twin is created by Packwise to make the involved logistics transparent.

Hard- and software in a nutshell

The solution offered combines an easy to install sensor with Software as a service (SaaS). Data is collected and transferred fully autonomously into the platform. Here extensive information about the goods is accessible. On top of that, the system analyses the data to map the supply chain processes for automatisation. In case of unintended events, various alerts can be triggered and concrete counteractions are provided for the operators.

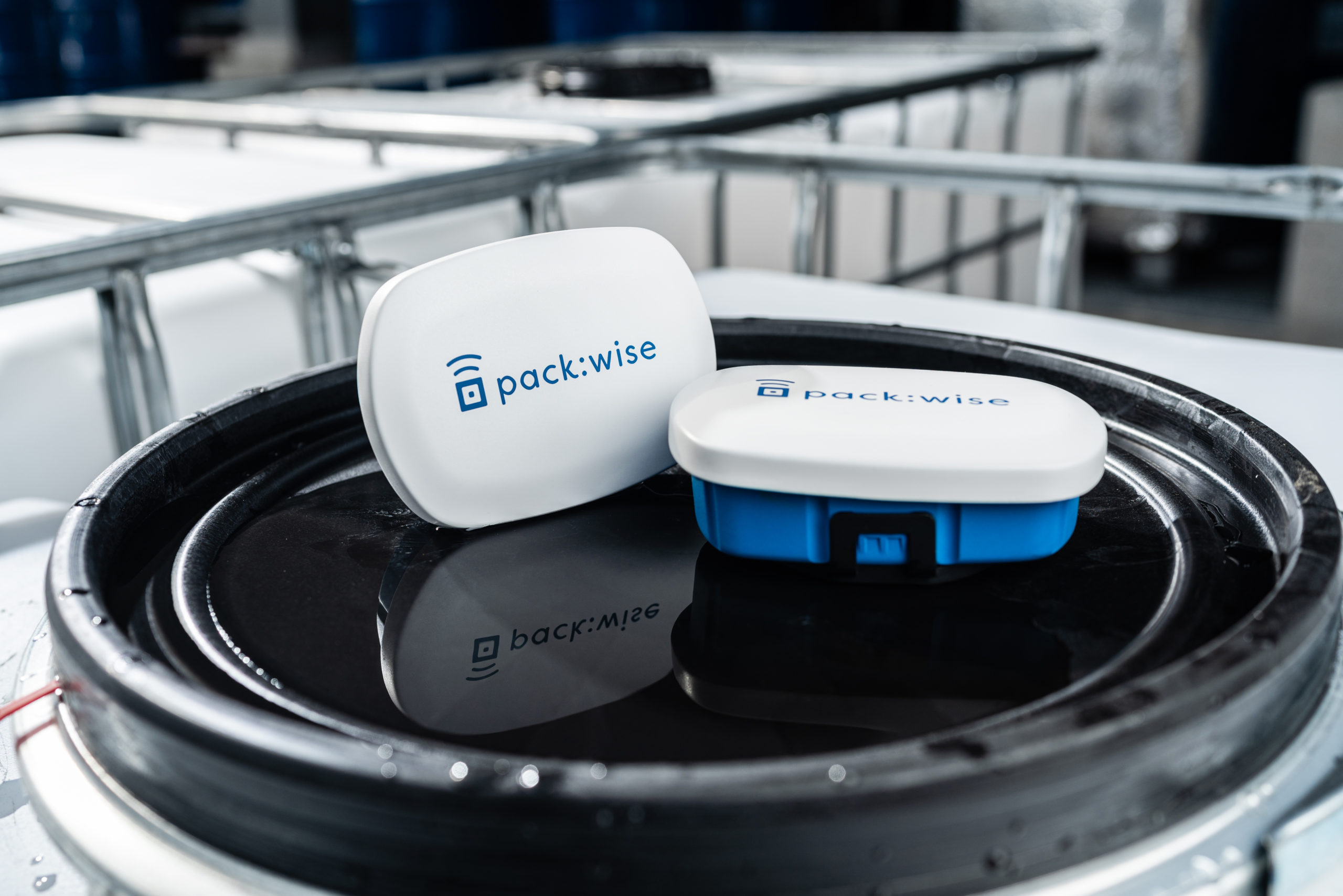

Plug & Play sensor

The IBCs are tracked by a couple of sensors in a single device. It can be attached within minutes by almost everybody. Radar is used to monitor and determine the fill level. GNSS technology is used to allow correct geolocation. An IMU is able to detect shocks or movements. And finally, the temperature is tracked as well. All data is transferred via either NB-IoT, LTE Cat M1, WiFi, GSM or BLE to be present in the IoT data platform. For reliable operations, the device is IP 68 certified.

Power management & encryption

Ultra-low-power processors and a high-performance energy concept allow a configuration to last up to 5 years under normal circumstances if sending intervals are set to 1 per day. The wireless data transfer is end-to-end encrypted for maximum data security. To integrate into existing ERP systems which are common in the logistics sector Packwise offers an API solution.

Smart logistics

As a result, Packwise achieves highly optimised logistic processes without significant additional workload at low costs. The optimisation is reflected in fewer losses of containers, better fleet management and a higher response rate in case of accidents. On top of that geo-located asset tracking is an enabler for efficient usage of existing containers, shorter transits and finally time-saving, due to shorter transport cycles.

Contact: packwise.de

Galileo for higher accuracy

Packwise implemented Galileo to benefit from its higher accuracy, better indoor signal quality as well as a civilian operator.